0

Sites

0

Core areas

0

million Euro revenue

0

Employees

Competencies

Punching & deep drawing

A total of more than 50 hydraulic presses from 20t to 1,350t and eccentric presses up to 630t pressing force are available for the production of punched and drawn parts in progressive dies, as manual transfer or with automatic transfer. All non-ferrous metals (austenites and ferrites), cold and hot strips from coil or sheet material with a material thickness of 0.3mm to 6mm can be processed.

Laser & bending

2D laser cutting with the latest technology: 8kW solid-state laser with automatic loading and unloading. We cut steel parts with cutting gas oxygen up to 25mm; cutting gas mixed gas up to 25mm; steel parts with cutting gas nitrogen up to 12mm, aluminum and stainless steel parts up to 25mm and brass and copper material up to 10mm. Our press brake is designed for a bending length of 4,000mm. The maximum pressing force of the machine is 1,700kN.

Bending tubes

We bend aluminum and stainless steel tubes with a tube thickness of about 1.5mm and a diameter range from 10mm to 30mm.

Welding

The great challenge in welding

is consistent quality at high volumes: Modern welding robots are available in our production for welding your parts in Pfullingen/G and Szekszárd/HU. For manual welding processes, we utilize the optimal technology for each application: spot welding, stud welding, roll welding, TIG and MAG, as well as brazing. Our highly trained welding specialists guarantee the best results.

Tool making

Complex tools require a very high level of know-how: modern CAM workstations with qualified staff are responsible for the design of the tools and also for an optimal design of the tool and fixture concept (such as punching/deep-drawing tools, welding fixtures and test fixtures). We have expanded our machine park with modern CNC machining centers and wire erosion machines.

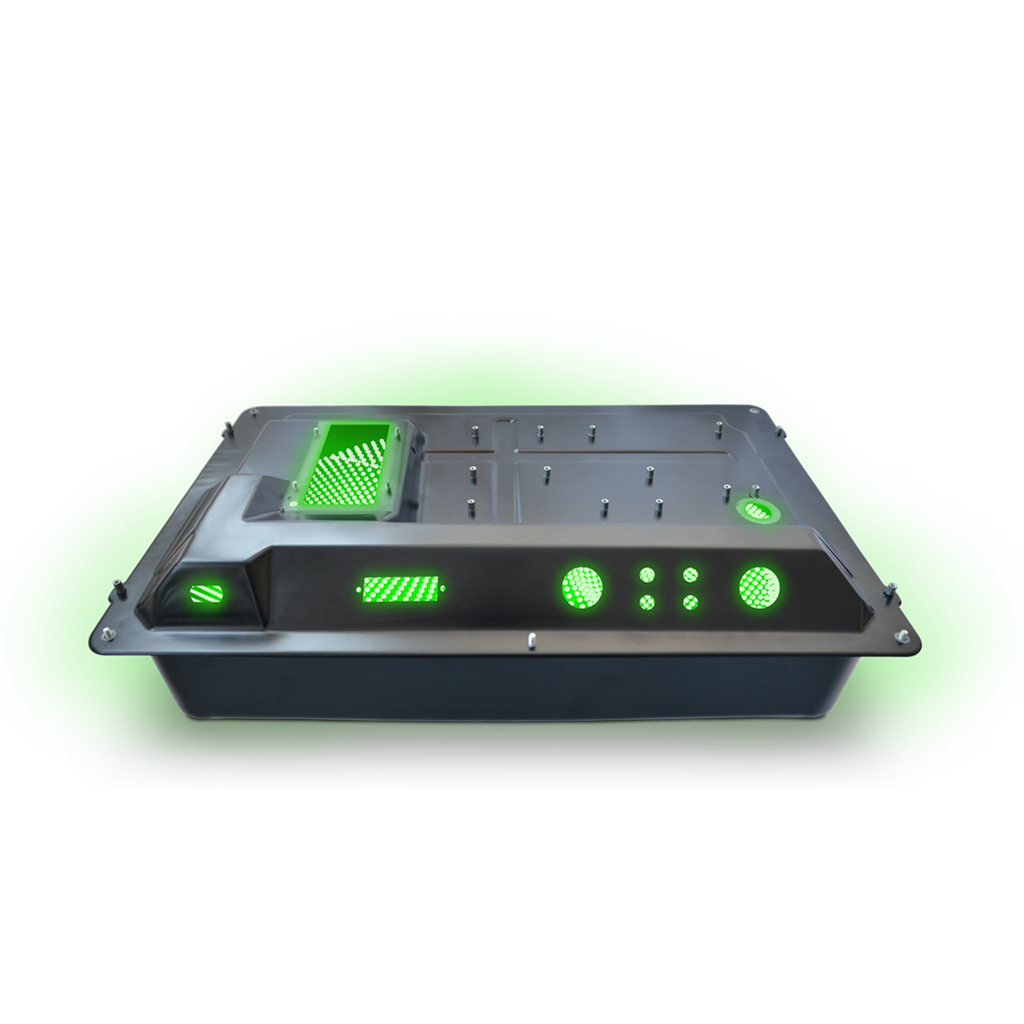

Powder coating

We refine your components and ensure corrosion protection and weather resistance with the process steps degreasing, parts washing and finally zinc phosphating. Our continuous baking oven is designed for hanging goods up to a size of 2000mm in length, 600mm in width and 1200mm in height.

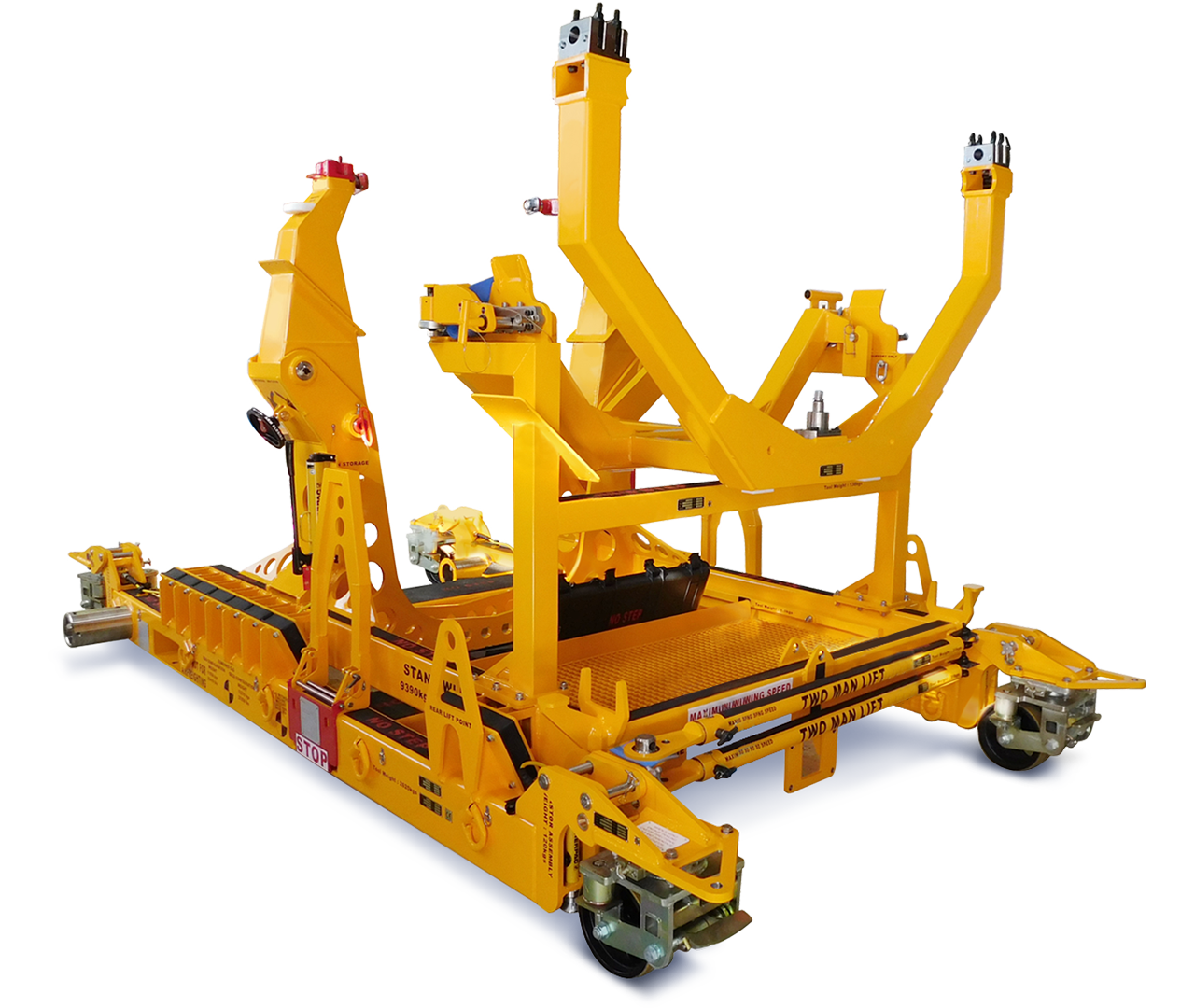

Assembly

Our customers not only request individual parts, but also complete assemblies. The combination of components manufactured by us with purchased parts and their timely procurement provides a complete solution in accordance with the customer's specifications. We perform this assembly with our experience and the skills of our employees.

Test & measure

Measurement technology is an important factor when it comes to quality assurance: we have three 3D coordinate measuring machines, each in D and HU. We perform metallographic welding examinations with microscope, hardness tests, optical production monitoring in our presses, welding process monitoring with HKS process technology, such as compression and tensile tests.

Engineering

Our project management and quality assurance test the realization of your 3D data and drawings in a production-ready manner during the pre-series phase. We perform feasibility tests, consult our customers in process development and product optimization to achieve a cost-effective product for the respective application.

Company

PRETTL Metal Components GmbH

Marktstrasse 155

72793 Pfullingen, Germany

BHG Alkatrészgyártó Kft.

7100 Szekszárd, Kesely´si Űt 4-8. Hungary

Sites

Certified Company